Modern diesel engine technology is under pressure to meet environmental standards and keep performance high. The industry needs new ways to balance power and protect the planet.

Caterpillar has answered these needs with their ACERT system. This stands for Advanced Combustion Emissions Reduction Technology. It was made to meet strict EPA emissions rules.

The system changes how Caterpillar engines burn fuel. Unlike old diesel systems, ACERT uses many methods to cut down on harmful emissions. It does this without losing engine power or efficiency.

This tech is key in today’s world of strict rules. It shows how new ideas in engineering can meet both high performance and green goals in diesel engine technology.

ACERT in Caterpillar engines is a big step forward in engine development. It shows the company’s dedication to green power without losing performance.

The Evolution of Diesel Engine Technology

Diesel engine technology has seen huge changes from Rudolf Diesel’s first patent in 1893. It has moved from simple mechanical parts to advanced electronic controls. This is a major leap in creating power.

Historical Context and Pre-ACERT Systems

Early diesel engines used mechanical fuel injection with poor precision. These systems had fixed timing and patterns, no matter the conditions.

Manufacturers used simple mechanical governors to control speed. But, the technology was not advanced enough for perfect combustion under different loads.

Limitations of Traditional Diesel Combustion

Old systems had incomplete fuel burning and lots of smoke. Operators had to choose between power and being green.

Controlling nitrogen oxide emissions was hard. Particulate matter caused maintenance issues and shortened engine life.

Fuel efficiency was low because of uneven combustion. This made advanced combustion technologies urgent.

Development of ACERT by Caterpillar

Caterpillar decided to innovate in the early 2000s, avoiding traditional EGR systems. This choice led to EPA penalties at first, but their new tech eventually paid off.

They launched ACERT engines in 2003 after lots of research. This was a big step forward in reducing emissions.

Key Innovations and Patents

Caterpillar got many patents for their electronic fuel injection system. It allowed for precise injections in each cycle.

They also made big strides in air management. These advances improved air-fuel mixing in all conditions.

Combining electronic controls with hydraulic actuation was a game-changer. It led to huge emissions reduction and kept power high.

What Is ACERT Technology

ACERT is Caterpillar’s advanced way to manage diesel engines. It combines precise engineering with digital systems to boost combustion efficiency. This technology links several systems to get the best performance and meet strict emissions rules.

Core Principles and Definition

At its core, ACERT technology focuses on managing combustion fully. It doesn’t just think about emissions later. Instead, it handles the whole combustion process through integrated systems.

The system’s smart part is its ability to adjust in real-time. This makes it different from old systems that can’t change as easily.

How It Differs from Conventional Systems

Old diesel engines use mechanical systems that can’t adjust much. ACERT’s digital setup lets it control each combustion event precisely. This is something mechanical systems can’t do.

ACERT keeps engine performance high while cutting down on pollution. This is a big change in how diesel engines are made.

Components of the ACERT System

The ACERT system has four main parts: advanced fuel injection, smart air management, electronic controls, and exhaust aftertreatment. Each part is key to the system’s success.

The heart of ACERT is its electronic controls and sensors. These sensors watch engine conditions like speed, air and fuel temperatures, and exhaust gases.

This info lets the system make quick changes to improve combustion. The electronic control unit uses this data to manage all parts of the system.

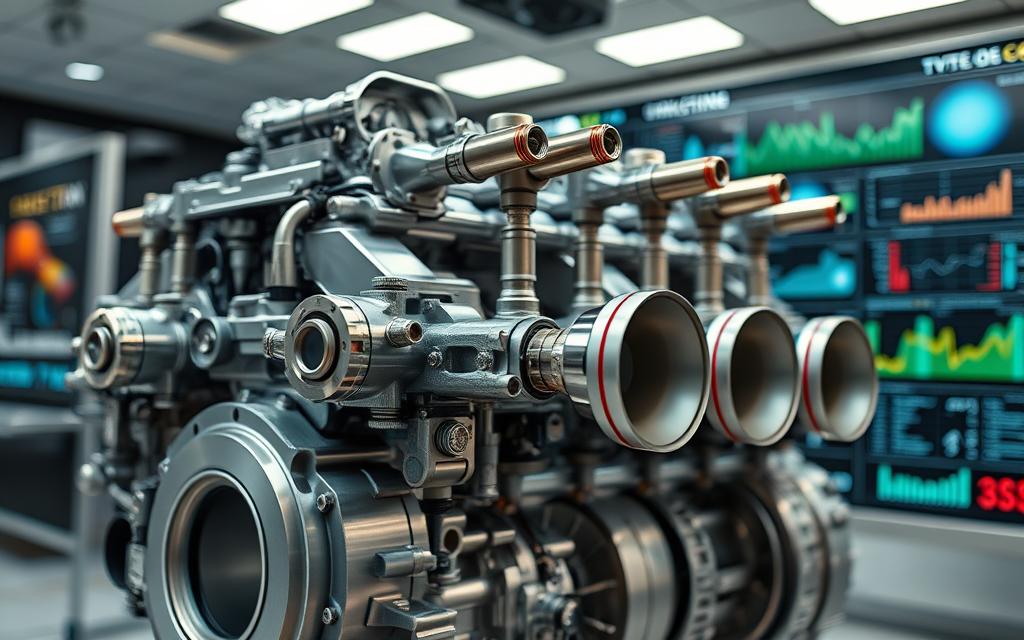

Fuel Injection Mechanisms

ACERT uses two main fuel injection systems. The Hydraulic Electronic Unit Injection (HEUI) system uses hydraulic pressure for precise fuel delivery. The Mechanically Actuated Electronic Unit Injection (MEUI) system mixes mechanical and electronic control for strong performance.

Both systems inject fuel at high pressures with exact timing. This leads to better fuel atomisation and more complete burning. This means better efficiency and lower emissions without losing power.

The Advanced Combustion Process in ACERT

Caterpillar’s ACERT technology is a new way to burn diesel fuel. It changes how engines handle air, fuel, and spark. This system is very efficient because it uses many parts working together.

Stages of Combustion Optimisation

The ACERT system improves combustion in two main ways: better air management and precise fuel delivery. These two systems work together to make sure fuel burns completely and efficiently.

Air Management Techniques

ACERT engines use a special dual-stage turbocharger. This system makes sure air is delivered efficiently. First, exhaust gases go through a high-pressure turbocharger, then a larger low-pressure one.

Intake air goes the other way, making a very efficient compression system. A water-to-air pre-cooler system also helps by cooling the air before it burns. This makes the air denser, so more oxygen can burn the fuel.

This leads to better fuel burning and less pollution.

Fuel Mixing and Ignition

The timing of fuel injection is very precise. An electronic control unit decides when to inject fuel based on many engine factors. This makes the air and fuel mix more even.

This careful planning helps achieve perfect burning conditions. The system works well because of this precise control.

Role of Electronics in Combustion Control

Modern electronics are key to the ACERT system. They use sensors and processors to watch the engine and adjust things quickly.

Real-Time Adjustments for Efficiency

The electronic control unit makes tiny changes to fuel injection timing and amount. These quick changes help the engine perform well under different loads.

This system keeps the engine running efficiently, whether it’s at full power or just idling. The technology ensures consistent performance.

The following table shows how electronics manage important combustion factors:

| Parameter Monitored | Adjustment Made | Resulting Benefit |

|---|---|---|

| Air Temperature | Fuel injection timing | Improved combustion efficiency |

| Engine Load | Turbocharger boost pressure | Optimal air-fuel ratio |

| Exhaust Quality | Injection quantity | Reduced emissions |

| Engine Speed | Multiple injection events | Smoother power delivery |

This detailed approach to managing combustion lets ACERT engines meet strict EPA compliance standards. The use of advanced turbochargers and electronic precision makes ACERT engines the best in diesel technology.

Benefits of ACERT Technology in Diesel Engines

ACERT technology is a big step up in diesel engine design. It brings many benefits, like better performance and less harm to the environment. These advantages help equipment owners and protect our planet.

Improved Fuel Efficiency and Economy

ACERT systems make fuel go further by burning it more efficiently. This means less waste and better use of energy. Users often find they use less fuel than with old diesel engines.

The smart air management system is key to this efficiency. It controls air intake and exhaust to ensure fuel burns completely.

Case Studies and Data Analysis

Studies show great results. Construction gear with ACERT uses 8-12% less fuel over time. Mining gear saves even more because it works under heavy loads.

Long-term data from fleets also shows big savings. One company saved over 150,000 litres of diesel a year. These savings cut down on costs and pollution.

Reduction in Emissions

ACERT technology cuts down on harmful emissions like nitrogen oxides. It does this by controlling combustion temperatures. This means less need for aftertreatment systems.

It also reduces harmful particles in exhaust. This is because fuel burns more completely. This makes exhaust cleaner and helps the environment.

Meeting EPA and International Standards

ACERT engines meet tough EPA standards easily. They do this without losing performance or efficiency. They also meet international rules thanks to their design.

In Europe, ACERT meets Stage V standards. It controls emissions well while keeping engines powerful. This is good for both the environment and engine performance.

Enhanced Engine Performance and Durability

ACERT engines have superior power output and quick response. Electronic control ensures top performance at all times. This means better torque and smoother power.

It also makes engines last longer by keeping them at stable temperatures. This reduces wear and tear. It means less need for repairs and longer engine life.

Long-Term Reliability Metrics

ACERT engines keep going strong for over 15,000 hours. They last 20-30% longer than old engines. This means lower costs over time.

They also need less maintenance, which means less downtime. The system can spot problems early. This keeps equipment running smoothly and efficiently.

Applications of ACERT Technology

ACERT technology is very versatile and is used in many industries. It provides clean power solutions where they are needed most. This innovative system works well in tough environments that need top performance and care for the environment.

Use in Caterpillar Engines and Machinery

Caterpillar uses ACERT technology in its wide range of equipment, mainly for heavy-duty tasks. It keeps power up while cutting down on emissions. This makes it perfect for Caterpillar’s top machines.

Examples in Construction and Mining Equipment

In construction, ACERT powers big machines like excavators, bulldozers, and wheel loaders. These machines meet strict emission rules without losing performance. They can work in cities with tight pollution rules.

Mining also benefits from ACERT technology. Huge haul trucks and underground mining gear use it. This helps keep mining productive while reducing harm to the environment in sensitive areas.

Adoption in Other Industries

ACERT technology is also popular in other areas needing reliable, clean diesel power. It can fit different needs and rules.

Marine and Power Generation Applications

Marine vessels use ACERT to meet global emission rules. It helps ships cut down on harmful emissions while keeping their range and power. This is a big help for ship owners.

In power generation, ACERT engines are used for backup and constant power. They make electricity with fewer emissions. This is good for places near people or in areas that need to be protected.

The technology’s ability to work in many areas shows its importance. It helps solve today’s environmental problems while keeping things running smoothly.

Comparing ACERT to Other Advanced Combustion Systems

ACERT is unique because it combines mechanical and electronic systems. This is different from other advanced systems. It works better in many ways.

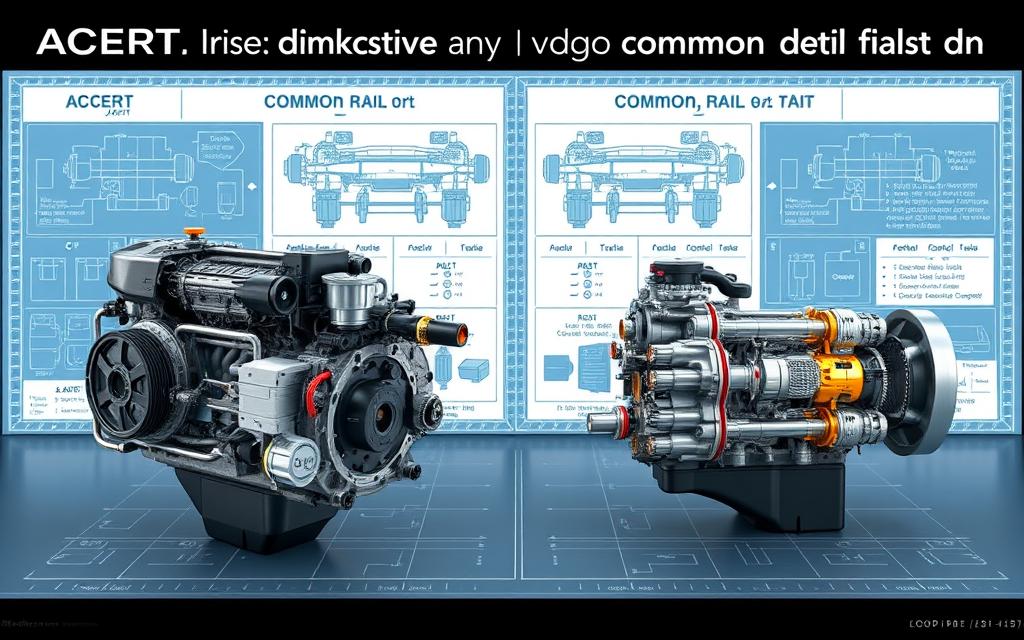

ACERT vs Common Rail Systems

Common rail systems are another way to improve diesel engines. They both aim to make combustion better. But they do it in different ways.

ACERT uses HEUI system and MEUI system for fuel control. These systems are reliable. Common rail systems use high-pressure fuel rails for injectors.

Performance and Cost Differences

ACERT systems are more durable for heavy-duty use. They handle tough conditions better than common rail systems. They also cost less to maintain over time.

Common rail systems might save fuel in lighter use. But they can fail in harsh conditions. ACERT is more cost-effective in the long run.

ACERT vs SCR and DPF Technologies

SCR and DPF systems are for cleaning exhaust, not improving combustion. ACERT uses them together for better emissions control.

ACERT’s combustion reduces emissions at the source. SCR handles nitrogen oxides later. This combo is more effective than each system alone.

Complementary and Competing Features

ACERT includes SCR and DPF in its design. This makes emissions control more efficient. It also means less maintenance.

ACERT is cheaper and better at reducing emissions than EGR systems. It’s a strong choice for modern diesel engines.

| Technology Type | Emission Reduction Approach | Fuel Efficiency Impact | Total Cost of Ownership |

|---|---|---|---|

| ACERT System | Combustion optimisation + aftertreatment | Improves efficiency by 8-12% | Lower long-term maintenance |

| Common Rail Only | Primarily combustion control | Improves efficiency by 10-15% | Higher electronic component costs |

| Standalone SCR/DPF | Exhaust aftertreatment only | May reduce efficiency by 3-5% | High filter replacement costs |

| Traditional EGR | Exhaust gas recirculation | Reduces efficiency by 5-8% | Moderate maintenance requirements |

The table shows ACERT’s balanced performance. It’s the best choice for emissions control because it excels in many areas.

Challenges and Limitations of ACERT Technology

ACERT technology has many benefits but also faces some challenges. These issues are both technical and related to market adoption. They affect how well the technology works in real life.

Technical and Manufacturing Hurdles

ACERT systems are complex, leading to technical challenges. They need precise manufacturing and special production methods. This is because they have many advanced parts.

Complexity and Maintenance Requirements

ACERT systems have advanced electronics and many parts. They need special maintenance. This makes maintenance a big challenge.

| Maintenance Aspect | Conventional Systems | ACERT Systems | Special Requirements |

|---|---|---|---|

| Diagnostic Tools | Basic mechanical tools | Advanced electronic diagnostic equipment | Specialised software and training |

| Component Replacement | Standard mechanical parts | Precision electronic components | Manufacturer-specific parts |

| Technical Expertise | General mechanical knowledge | Advanced electronics training | Certified technicians required |

| Scheduled Maintenance | Routine service intervals | Complex monitoring systems | Continuous system analysis |

The combustion optimisation in ACERT systems needs regular checks. Specialised knowledge is needed to keep them working well. Keeping the exhaust aftertreatment system in good shape is key for meeting emissions standards.

Market Adoption Barriers

Several factors slow down the adoption of ACERT technology. These barriers affect both manufacturers and users thinking about switching.

Cost Considerations for End-Users

ACERT engines cost more than traditional ones at first. This extra cost includes the initial price and ongoing maintenance. You also need special tools.

Many face budget issues when looking at the total cost of owning ACERT engines. The need for skilled technicians and specific tools adds to the cost.

Despite these issues, the benefits of combustion optimisation and exhaust aftertreatment make ACERT worth it. It’s good for those who value efficiency and meeting emissions standards.

Future Developments in ACERT and Diesel Combustion

Diesel engine technology is changing fast, with ACERT systems leading the way. As rules get stricter and new power options appear, the future looks bright. Advanced combustion systems are set to bring exciting changes.

Ongoing Research and Innovations

Caterpillar is dedicated to improving ACERT technology. Their teams are working hard on better combustion and emissions control. They’re creating advanced fuel systems and electronic controls for top efficiency.

One big innovation is the variable geometry turbo. It manages airflow better, leading to cleaner burns and better engine performance.

Integration with Hybrid and Electric Systems

The future of ACERT is linked with new power systems. Combining diesel with hybrid electric tech is showing great promise. This mix could make engines more efficient and powerful.

This blend lets diesel engines work best while electric systems handle extra power. It could change how heavy machinery and vehicles move.

Predictions for Industry Trends

The diesel engine world is set for big changes. Engines will need to adapt to new needs. We’ll see engines made for specific jobs, each working better in its own way.

Marine applications will see a lot of growth. Diesel engines are key for big ships and offshore work. They need to be strong and efficient for long, tough jobs.

Sustainability and Regulatory Impacts

New rules will guide ACERT and other techs. Tighter emissions laws will push for cleaner, more efficient engines. This will drive innovation in how we treat emissions.

The focus on sustainability goes beyond just meeting rules. It’s about looking at the whole life of a product. This includes how it’s made, used, and recycled.

Conclusion

ACERT technology is a major breakthrough in diesel engine development. It combines strong power with strict environmental rules. This shows Caterpillar’s deep commitment to innovation.

The key to its success is the use of advanced parts, like the diesel oxidation catalyst. These parts work together to cut down harmful emissions a lot. The air management system makes sure the burning process is clean and efficient.

Caterpillar’s ACERT system shows that you can have power and be responsible at the same time. It meets the needs of heavy industry for power and durability while following global emissions rules. This balance is its biggest achievement.

ACERT is a key technology that shapes new developments. Its focus on clean combustion and precise control sets the stage for future improvements. ACERT makes sure diesel power stays a clean, efficient, and vital option for many years.

FAQ

What is ACERT technology and why is it significant in modern diesel engines?

ACERT, or Advanced Combustion Emissions Reduction Technology, is Caterpillar’s innovative system. It meets strict environmental standards, like the EPA’s, without losing engine performance. It uses precise electronic controls to improve combustion, cutting emissions and boosting efficiency.

This technology is key today, as reducing pollutants is a top priority.

How does ACERT differ from traditional diesel engine systems?

ACERT is different from old diesel engines. It uses advanced electronic systems, not just mechanical fuel injection. It also has dual turbochargers and sensors for real-time adjustments.

This ensures better combustion and emissions control.

What are the key components of the ACERT system?

The ACERT system has several advanced parts. These include electronic control modules, high-precision fuel injectors, and dual-stage turbochargers. It also has sensors to monitor engine conditions.

Together, they manage combustion parameters dynamically, improving efficiency and reducing emissions.

How does ACERT improve fuel efficiency and reduce emissions?

ACERT boosts fuel efficiency by controlling combustion precisely. This leads to more fuel being burned completely, reducing waste. It also lowers emissions through advanced strategies like staged combustion.

Its use of turbochargers and pre-coolers further decreases pollutants, often exceeding standards.

In which industries and applications is ACERT technology commonly used?

ACERT is used in Caterpillar’s construction and mining equipment. This includes excavators, bulldozers, and haul trucks. It’s also in marine engines and power generation systems, where emissions rules are strict.

Its versatility makes it ideal for heavy-duty applications with strict emissions needs.

How does ACERT compare to other emissions reduction technologies like common rail or SCR systems?

ACERT offers more integrated and precise control over combustion. This often results in better performance and durability. While SCR and DPF systems can complement ACERT, it focuses on optimising combustion to reduce emissions at the source.

This might lower the need for aftertreatment.

What are some challenges or limitations associated with ACERT technology?

ACERT’s main challenges include its technical complexity. It requires special knowledge for maintenance and repair. It also has higher initial costs than conventional engines.

Manufacturing these advanced systems is challenging due to the precision needed for components. These factors can slow its adoption, despite its long-term benefits.

What future developments are expected for ACERT and diesel combustion technology?

Research aims to improve ACERT, meeting tighter emissions regulations. Future developments might include hybrid or electric system integration. Innovations in electronic controls and combustion optimisation are also expected.

These advancements will keep ACERT at the forefront of diesel engine technology.

How does ACERT contribute to engine durability and reliability?

ACERT optimises combustion, reducing stress on engine components. This enhances durability and reliability. The precise control of fuel injection and air management prevents issues like knocking or incomplete combustion.

This leads to longer engine life and consistent performance, even under demanding conditions.

Can ACERT technology be retrofitted to older diesel engines?

Retrofitting ACERT to older engines is not feasible. It’s designed as a complete solution during manufacturing. Adapting it to older models would require extensive, often impractical or cost-prohibitive, modifications.